SynergySorb® sorbents and sorbent products are highly efficient for

Oil spill response

* The image shows an oil spill where no SynergySorb® sorbents and sorbent products were used

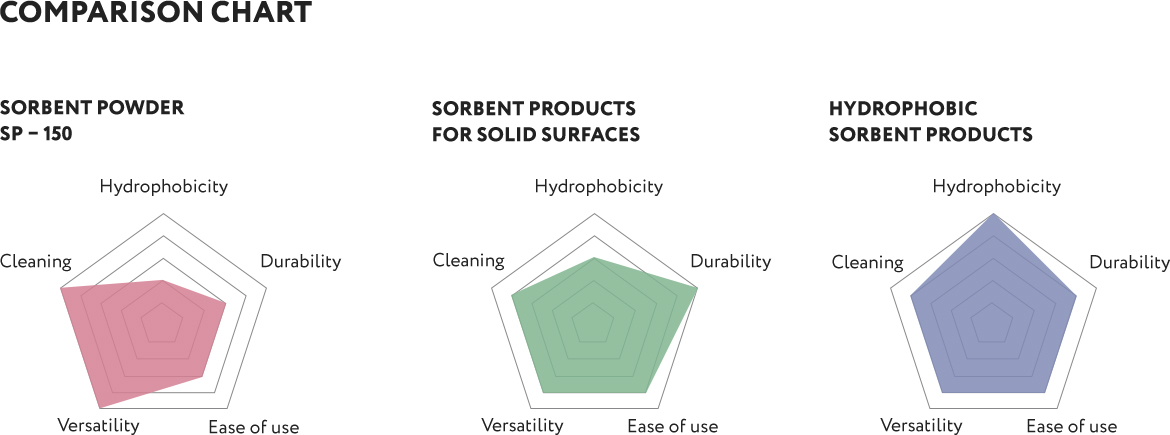

Sorbent powder, sorbent products for solid surfaces, and hydrophobic sorbent products are applicable for oil spill response activities.

SynergySorb® sorbent powder SP-150 is used in response efforts to oil spills on water, land, and solid surfaces to completely clean up the oil and iridescent film. The sorbent is applied to the contaminated area by improvised means (shovels, scoops), blowers, and sandblasting guns, as well as straight from the tare bags. Removal of the waste sorbent is achieved through improvised means, including brushes, brooms, shovels, and industrial vacuum cleaners.

SynergySorb® sorbent products for solid surfaces are used in response to oil spills on land and solid surfaces. Its wear-resistance to heavy-duty shoes and trucks facilitate the oil spill response work. Sorbent products are laid on the oil spots in contaminated areas.

SynergySorb® hydrophobic sorbent products are used in response efforts to oil spills on water and coastlines. A strong water-repellent response, durable buoyancy, and the stability of the sorptive properties, even after a long period underwater, are significant advantages in the use of hydrophobic sorbent products on lumpy water. Sorbent products completely absorb the petroleum products and do not leave an iridescent film. Saturation control of sorbent products through visual checks is conducted at least every 24 hours.

Waste sorbent recycling is an important modern environmental requirement. All types of SynergySorb® sorbents and sorbent products compare favourably with other sorbents and sorbent products because there is absolutely no need for disposal and utilisation of SynergySorb® products by clients. Hydrocarbon-saturated waste sorbents and sorbent products are placed in any type of container and are delivered back to the dealer. After the primary treatment, the dealer in turn delivers pre-processed sorbent products to the manufacturer for further use in the production process.

Complete waste sorbent recycling

Demonstration of various scenarios of industrial cleaning by SynergySorb® sorbents and products.

Introductory information on the properties, origin, and use of SynergySorb® sorbents and sorbent products.